Every industrial project that uses water needs a way to manage its wastewater, but not every slurry solution works for every type of project. The type of water filtration that works best for a particular site depends on the specifics of the project, but two of the most popular options are the filter press and the screw press.

How do Screw and Filter Presses Work?

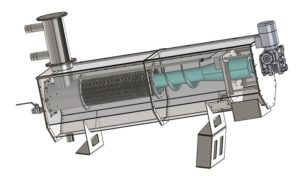

Filter presses and screw presses differ in their fundamental modes of operation. A screw press features a metal screw designed to compact slurry water into a small cavity, forcing water through a filter cake and filter element.

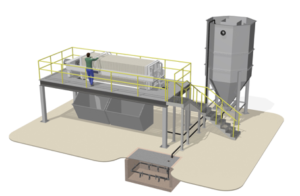

Meanwhile, a filter press uses a hydraulic pressure system to force slurry water through a series of large filter cakes. Most presses also have an external slurry pump, which allows the press to increase pressure and filter wastewater with even more force.

Which System is Right for Me?

Both filter presses and screw presses have their strengths and weaknesses. The best system for you depends on your intended application.

Filter presses feature a larger and more efficient filtering area and pressure control, which allows them to filter a larger variety of slurries. This versatility makes the filter press much more popular among industrial projects like stonecutting and construction.

In contrast, a screw press is typically used for more specific applications, such as juicing. While this makes screw presses the superior option for wineries and juice bottlers, they’re next to useless for projects that need to filter more abrasive slurry, like concrete or stone. Screw presses are also not recommended for any application that requires ultra clean water or a dry filter cake product.

Find the Right System for You at Full Circle Water

At Full Circle Water, we provide comprehensive slurry management solutions for any industry. Chat with one of our slurry pros today, and we’ll help you find a system that works for your project.