Full Circle Water offers a variety of state-of-the-art automated filter presses for use in countless applications. The automatic filter press is the perfect machine for applications that require super clean water. Without any hands-on work from you or your employees, you can rely on dry cakes and highly filtered water that is ready to be reused. With a quick processing time, the automatic filter press is as good as it gets when it comes to treating wastewater.

AFP1

AFP2

AFP5

AFP25

Needing Help With Your Slurry

Our team will work diligently to make sure all your slurry problems are solved.

Standard systems come in sizes from 1/3 to 5 cubic foot capacity. Larger sizes are available and can be designed to your specifications. Our automatic filter presses can cycle in as little as ten minutes. The automatic filter presses come standard with non-gasketed cloth, though gasketed style cloths and plates are available as an option.

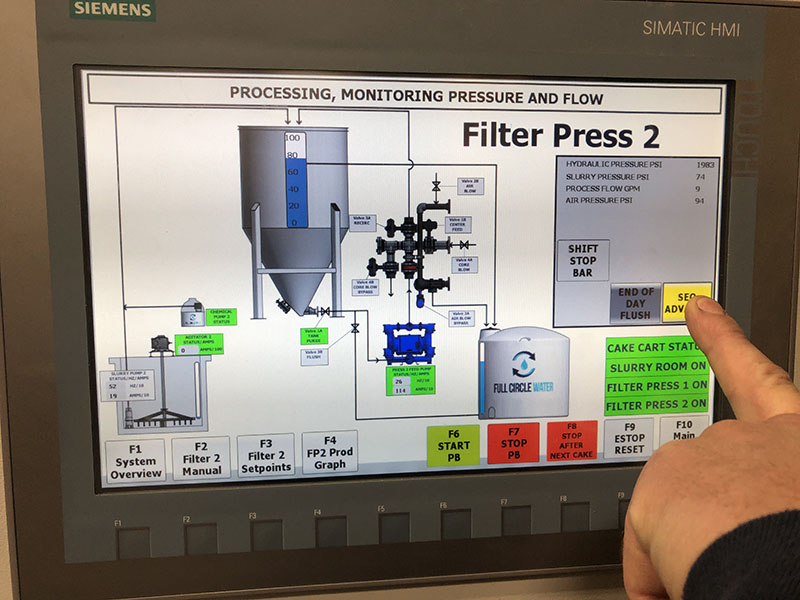

All automatic presses are controlled via motorized hydraulics which offer longer life and lower operating costs verses air over hydraulic components commonly found on filter presses. Controls can be customized to provide full automation with your existing water treatment equipment.

- Fully automatic filter presses

- Allow remote monitoring and operation

- Greatly reduce labor and maintenance

- Engineered for your application

- Turnkey solutions with integrated HMI and controls

- Full automation available

Our equipment is designed to handle even the toughest slurry. Whether you’re in the concrete, metal finishing, stone fabrication, or food and beverage industry, our filter presses will give you the results you need.