Needing Help With Your Slurry

Our team will work diligently to make sure all your slurry problems are solved.

Full Circle Water has thousands of satisfied clients throughout North America

We manufacture equipment right here in St Joseph, MN. We are family owned and believe you should be demanding of the equipment we manufacture.

Solutions for Concrete

Working in the concrete industry provides wastewater challenges that differ from the stone industry. Suspended solids will need to be removed, the water will need to be filtered, and the pH will need to be balanced. The concrete process is unique in that it typically raises the pH level of the water, which requires balancing before it can be discharged or reused. Local, state, and federal regulations, laws, and ordinances must also be met.

Full Circle Water understands the need for wastewater solutions that not only meet your expectations, but exceed them. We aim to provide cost-effective solutions that will save you money and save you time. Our equipment is reliable and we take the time to find the right equipment for your operation. Not only do we offer turnkey packages, we offer equipment that can be fully customized to meet your needs. We will meet with you to discuss your needs and goals so we can provide you the best solution.

Each slurry situation is different. We have a variety of solutions that allow for water reuse or environmental disposal. Products perfect for the concrete industry include slurry silo systems, rapid settlement systems, filter presses (automatic and semi-automatic), portable filter presses, ready mix plants, and pH balancers. Whether you have a small operation or a large operation that can’t afford any downtime, our equipment is designed with you in mind and is engineered utilizing the latest technology. We can work with concrete grinding and grooving operations, precast concrete manufacturers, concrete coring specialists, concrete cutting and grinding companies, concrete floor polishing teams, and concrete roll out firms.

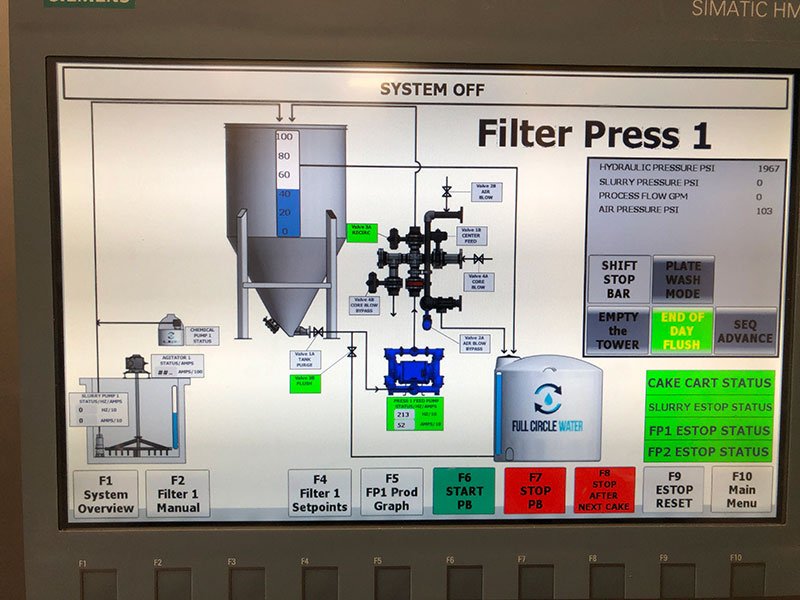

Filter Press

Full Circle Water filter press equipment packages include systems designed for a wide variety of concrete slurry water applications. These include systems to handle precast, washout and wash down, cutting, grinding, and polishing. Just about any application where water and concrete fines produce slurry. After the concrete slurry water is effectively treated it can then be reused in the process.

Our filter press systems are designed with robust pumps, piping, and valving. We also offer controls to handle the harsh pH and alkalinity associated with concrete slurry. The equipment can be incorporated into an existing pit and screen separation process, or as a complete turn key system.

Manual, semi-automatic, and automated filter press systems are available to clarify your slurry water and to dewater the sludge so it is convenient to haul and dispose of. The systems can be installed permanently at a fixed location or skid and trailer mounted where portability is important.

Our filter press systems are an ideal pairing of proven technology and proven process to deliver consistent performance. Specific sizes, models, pumps, and controls are available to match your needs.

Slurry Silo

Full Circle Water manufactures our Slurry Silo decanting towers to meet the demands of the concrete industry. These silos are ideal for applications where lower volumes of solids and water need to be separated cost effectively. Convenient dewatering bags can be used to dispose of the sludge collected out of the concrete slurry water, or a filter press can be added to dewater the sludge.

The Slurry Silo requires less maintenance than most water systems in the concrete industry and typically costs much less per gallon of slurry processed. When sized properly the equipment removes approximately 95% of the solids in real time – as slurry is produced it is processed and cleaned for reuse or disposal.

The Slurry Silo can be equipped with a variety of options to meet your specific requirements. Typically the silos are permanently installed though they can be used on job sites and projects in the field if needed.

Rapid Settlement Systems

Full Circle Water’s unique Rapid Settlement Systems use inclined plate clarifier technology and are capable of removing very small fines from slurry water produced in the concrete industry. The clarifiers use very small amounts of polymers injected into the slurry stream as water is pumped into the systems. The design of the system ensures that small particles only need to settle 2 inches to be removed from the water as slurry makes its way through the tower.

Solids then collect in the bottom of the hopper and are conveniently discharged via an automated purge valve or are pumped through a filter press for further dewatering when necessary.

The RSS clarifiers represent the pinnacle of settling technology available today. They can be paired with a variety of options and configurations to meet just about any slurry water application. Many applications allow for the reuse of the water in the facility as well.

Concrete industry water regulations are challenging. Many different agencies can inspect and fine both for slurry discharge and for silicosis. The list of agencies implementing these is long. The federal government, OSHA, state governments, by county environmental departments, by municipalities, by state game and fish departments, and by waste water treatment plants. Also by other agencies such as groundwater associations, rural water districts, watershed districts, environmental and health departments. It can be daunting to say the least. Unlike many environmental engineering firms, we will offer quick sound advice on regulatory issues that impact your business The new silicosis standards require your concrete facility to carefully plan and manage processes to ensure the air quality standards are met. It is extremely important to utilize water and rinse water throughout most concrete facilities to keep dust to a minimum. Concrete facilities that have bodies of water nearby need to obtain water discharge permits from their state pollution control agency or the EPA. Please follow the links to the right for further information. Many firms lack the resources and expertise to understand industrial water and wastewater regulations. They worry daily about their discharge but fear the unknown costs to solve the problem. Unfortunately it is expensive and risky to be found in non-compliance. Pollution control authorities are more understanding of small infractions from a firm that is making an effort to comply with the regulations than from a firm that has made no effort. Full Circle Water is your partner to cost-effectively meet regulatory standards. Concrete slurry producers must to be aware that they are liable for the wastes they produce. Paying firms to dispose of these wastes does not eliminate this liability. It is important for you to understand the regulations that impact your business and to have a plan to effectively deal with them.